- Sala Blanca o Sala esterilizada

- Sistema HVAC

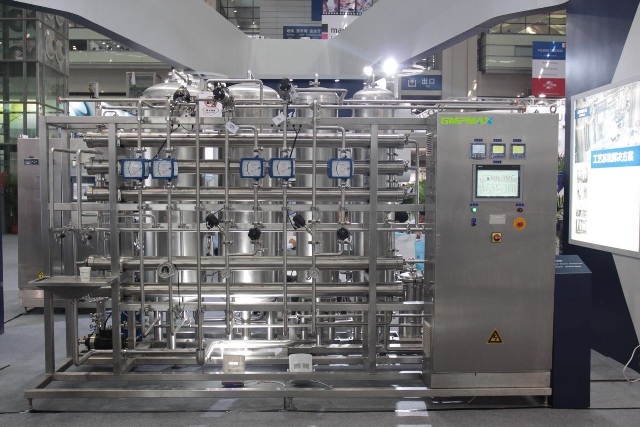

- Sistemas de aguas para la industria farmacéutica

- Tuberías de distribución sanitaria

- Sistemas de formulación

- Sistemas CIP/SIP

- Sistemas de control

- Producción de tabletas

- Producción de capsulas

- Producción Polvo Vial

- Producción de polvo en frasco

- Producción de líquidos en frasco

- Producción de gotas para los ojos

- Producción de tipo IV

- Producción de ungüentos, pomadas y cremas

- Producción de gelatinas blandas o gel

- Producción piloto

- Producción de ampollas

30H Reciprocating Water Cooled Chiller

Economical, Easy-to-Install Packaged Chillers Designed to Save Energy

Wider size range

Application versatility

Long range cost savings

Quiet, reliable operation

Installation ease

Units are designed to reduce installation time and costs. They arrive at the jobsite able to fit easily through a 36-in, wide opening due to their compact design. 30HK, HR units, come complete with cooler, condensers, compressors, controls, refrigerant charge, oil charge, and need only the addition of a condenser water supply, electrical power and chilled water distribution system.

A single location connection to electrical power adds to unit installation convenience. All internal piping and wiring is complete, and with all essential controls and protective devices installed at the factory, installation is completed in minimal time.

Operating reliability

Standard dual refrigeration circuits on 30H units (36 tons and up) save the day when units are undergoing service and regular maintenance. Units can continue to operate at part load avoiding prolonged shutdown of entire system. Status indicator lights on the integral control box inform the service technician where a problem is, and help the technician to correct the problem in minimal time. Lead/lag control is also available with 30h 036-280 chillers. This helps to balance operating hours between refrigerant circuits for increased system protection, reliability, and longer compressor life.

Units have the capability to start and pull down with up to 95F entering water temperature due to integra

MOP (maximum operating pressure) feature of the expansion valve. Multiple-step capacity control allows compressors to load or unload to match changing cooling load requirements. Also, multiple compressor units (above 36 tons) operate at much lower inrush current than large, single compressor units. With 4- compressor chillers the inrush kW is reduced to a mere 25% of the single compressor unit.

Compressors are mounted on heavy-duty spring vibration isolators to minimize vibrator, transmission to the building. Quiet operation is further assured by hot gas mufflers than dampen hot gas pulsations and provide smooth, trouble-free quiet performance.

Manual switch

At full load. 30H chillers provide EER°Øs (Energy Efficiency Rations) up to 14.1 Multiple compressors on a refrigerant circuit enhance part-load efficiency. Each circuit uses 100% of the heat exchanger surface at all times. optimizing performance at all loading conditions, especially part load, Since the chiller normally works at part load for 97% of its operating time, a substantial reduction in operating cost can be realized.

Refrigerant sight

On 06E compressors eliminates unnecessary compression of refrigerant gases during unloaded operation.

This substantially reduces part-load power consumption, resulting in an EER increase of as much as 39.5% at 33% load.

Liquid refrigerant subcooling

Means the coldest condenser water is used by the integral subcooler to increase system capacity without extra horse power. This means more cooling output per unit of electrical input.

Ease of service reduces cost

When the 30H is in need of inspection and service, saving time is of the essence. The reciprocating. Semihermetic compressor and electromechanical controls are familiar to technicians so that problems can be resolved quickly. Hinged access doors to service areas are another time and money saver enabling service technicians to avoid disassembly time. 30HK,HR water-cooled units have condensers that are cleanable to allow periodic maintenance which helps to prolong the life of the system.

|

Model |

Cooling Capacity |

||

|

kW |

104kcal/h |

Ton |

|

|

30HK026 |

86 |

7.5 |

24 |

|

30HK036 |

115 |

10 |

33 |

|

30HK065 |

224 |

20 |

64 |

|

30HK115 |

344 |

30 |

98 |

|

30HR161 |

448 |

40 |

127 |

|

30HR195 |

580 |

50 |

165 |

|

30HR225 |

694 |

60 |

197 |

|

30HR250 |

792 |

70 |

225 |

|

30HR280 |

895 |

80 |

255 |

Key Words:

Pharmaceutical Machinery, Pharmaceutical Engineering, Pharmaceutical Equipment,

Packaging Machinery, GMP Machinery, Pharmaceutical Industry, Pharmaceutical Technology

cGMP Service, cGMP Solutions, cGMP Validation